The product is made and supplied with the capacity of being self-priming.

However there are cases in which the self-priming capacity is not necessary to use self-priming pumps. During priming the pump obliges part of the water already under pressure to return to the suction part until a pressure value is reached at delivery whereby the system can be considered primed.

At this point the recirculating channel closes automatically. This phase is repeated each time the pump is switched on, even already primed, until the same pressure value that closes the recirculating channel is reached about 14psi (1 bar).

When the water arrives at the system intake already under pressure, it is possible to force the closure of the recirculating pipe, losing the self-priming capacity.

This obtains the advantage of eliminating the clicking noise of the pipe shutter each time the system is switched on.

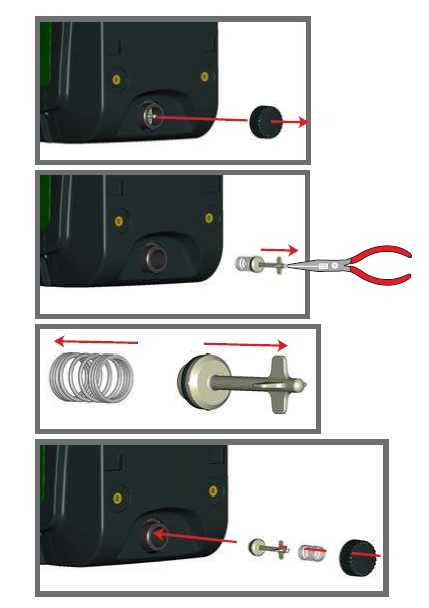

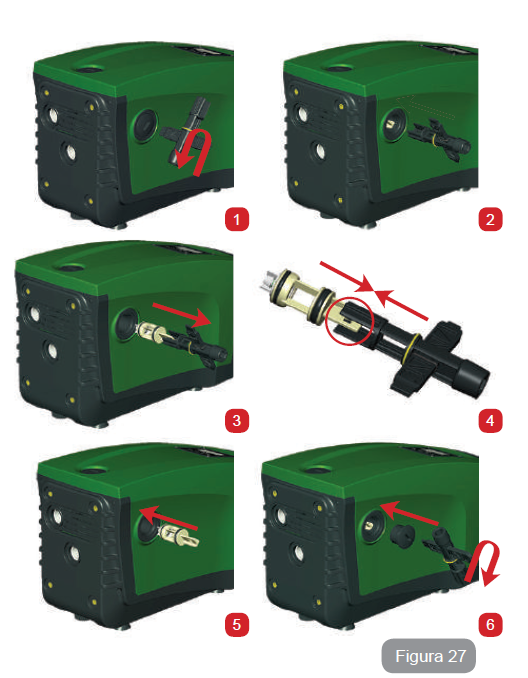

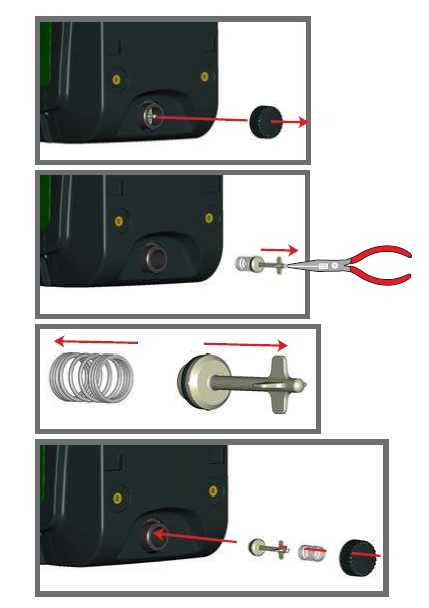

To force closure of the self-priming pipe, proceed as follows:

1. disconnect the power supply;

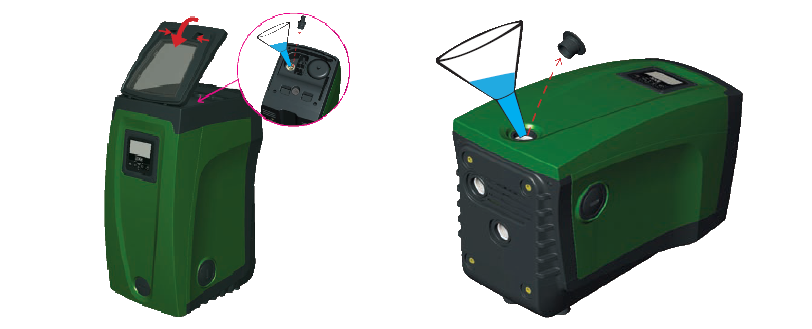

2. empty the system (unless you decide to inhibit self-priming at the first installation);

3. remove the drainage cap anyway, taking care not to drop the O-ring

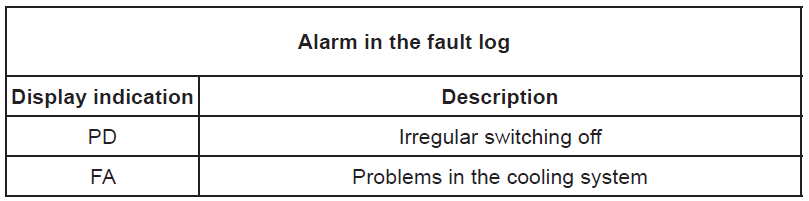

4. with the aid of pliers take the shutter out of its seat. The shutter will be extracted together with the O-Ring and the metal spring with which it is assembled;

5. remove the spring from the shutter; insert the shutter in its seat again with the respective O-Ring (side with gasket towards the inside of the pump, stem with cross-shaped fins towards the outside);

6. screw on the cap after having positioned the metal spring in side so that it is compressed between the cap itself and the with cross shaped fins of the shutter stem. When repositioning the cap ensure that the respective O-Ring is always correctly in its seat.

7. fill the pump, connect the power supply, start the system.