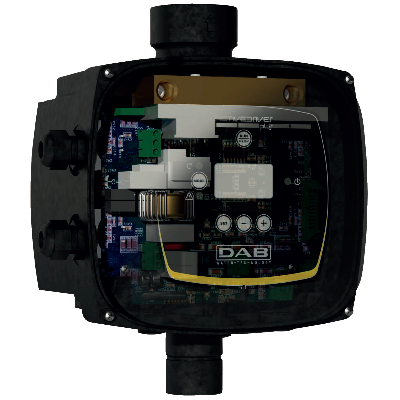

The ACTIVE DRIVER Plus family takes advantage of all the vast experience of DAB in electronics.

Active Driver Plus inverters are used for the control of hydraulic pumps. Their obvious fields of application are domestic and industrial constant pressure pumping systems.

Extremely innovative thanks to the dual processor technology and the compact sizes, Active Driver Plus inverters are also very quick to install, thanks to the easy to follow wizards.

Thanks to the always constant pressure, they provide the maximum levels of comfort.

The constant pressure is ensured through the control of the speed of the pump, so that it rotates at the minimum speed for guaranteeing the required pressure and flow rate. This brings significant energy savings, the lowest possible noise levels, and also contributes to increasing the life of the pump.

The Active Driver Plus family is extremely versatile, and includes inverters for all types of pumps, both single and three phase.

TECHNICAL DATA

- Line voltage: 115V and 230V single phase.

- Electric pump voltage: 115V and 230V single phase, 230V three-phase.

- Max Hp 115v 1~: ¾ Hp (14 amps max)

- Max Hp 230v 1~: 1.5 Hp (14 amps max)

- Max Hp 230v 3~: 2.0 Hp (10.5 amps max)

- Max Hp 480v 3~: 5.0 Hp (13.3 amps max)

- Frequency: 50 Hz - 60 Hz.

- Installation: vertical or horizontal.

- Max. Liquid temperature: 122°F.

- Max. Operational temperature: 144°F.

- Flow max: 66 gpm.

- Max. pressure: 188 psi.

- Pressure regulation range: from 15 to 188 psi.

- Connection In: 1 1/4” male.

- Connection Out: 1 1/2” female.

- Protection rating: IP55.

- Communication interface for sets: Yes, an Active Driver per pump.

APPLICATIONS

The units with Active Driver were designed and manufactured to meet the needs for constant pressure system used in many modern plumbing systems.

Constant pressure regulation is applicable to many sectors: Water supply for irrigation , industry, hotels, housing construction, thermal baths.

The basic concept that guided our Engineers in the development of these units was to manufacture a system that is simple, flexible and reliable.

ADVANTAGES

Constant pressure - Quiet operation - Economical - Reduced water consumption - Smaller footprint

(Expansion tanks not required) Less maintenance - Dry-running protection - Complete protection of the pump from faults.

The Active Driver inverter is a pump control device that includes the connections to the hydraulic system, a pressure sensor, a flow sensor, and an electronic frequency inverter. Active Driver is applied on the delivery of each electric pump, and regulates the rotation speed of the pump it is connected to, so that the pressure is kept constant in spite of variations in the required flow rate. The water flowing through the Active Driver Plus connections also contributes to eliminating the heat produced by the internal electric components.

OPERATION

Active Driver orders the pump to start as soon as it detects a request of water. The speed of the pump is (consistently) regulated at the minimum value that meets the request of the user. This ensures important energy savings. In this set, the second and third pump are activated in cascade when the first pump reaches the maximum rotation speed.The pump pressure may be adjusted by the user using the + and - buttons on Active Driver (usually all of the pumps are set at the same pressure level).

The pumps stop automatically when there is: Pump overload - dry-running - low voltage - Maximum pressure exceeded (adjustable) - Active Driver electronics overheating.

ACTIVE DRIVER FUNCTIONS DISPLAYED

- Pump operational frequency (Hz)

- Real-time pressure (psi or bar)

- Amperes absorbed by the pump

- Alarms.

ACTIVE DRIVER EXTERNAL CONNECTIONS (models M/T 2.2 only)

- Inputs: pump disabling, pressure switch, float against dry operation, second pressure setpoint.

- Outputs: two terminals with no potential for signaling alarms, pump stop, pump running.

DAB JET Self-priming centrifugal pumps for domestic use, also able to run in the presence of air bubbles, with cast-iron...

DAB JET Self-priming centrifugal pumps for domestic use, also able to run in the presence of air bubbles, with cast-iron...

DAB JET SS self-priming centrifugal pump for domestic use, also able to run in the presence of air bubbles, with...

DAB JET SS self-priming centrifugal pump for domestic use, also able to run in the presence of air bubbles, with...

DAB EUROINOX Multistage horizontal centrifugal pump, featuring extremely silent running suitable for domestic use for...

DAB EUROINOX Multistage horizontal centrifugal pump, featuring extremely silent running suitable for domestic use for...

Vertical multistage centrifugal pump suitable for small to medium user water systems. Suitable for pressurization units...

Vertical multistage centrifugal pump suitable for small to medium user water systems. Suitable for pressurization units...